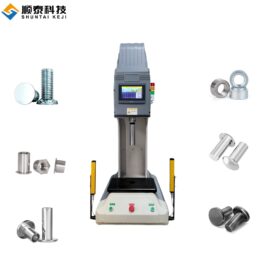

Riveting equipment

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

Stamping Equipment

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

| Pressure Range P | 2.8 KN |

|---|---|

| Stroke S | 50-200 mm |

| Riveting Time T | 0.1~9.9 S |

| Stroke Frequency N | 0.1~30 min⁻¹ |

| Max Die Height H1 | 345 mm |

| Min Die Height H2 | 345-S mm |

| Throat Depth A | 95 mm |

| Working Pressure | 0.3~0.8 Mpa |

| Operating Temperature | -30 ~ 50 ℃ |

| Worktable Size | 240×200 mm |

| Worktable Thickness | 30 mm |

| Overall Dimensions | 500×550×(920+S) mm |

| Weight | 60 kg |

| Power Supply | 220V 50Hz |

| Input Pressure | 0.3~0.8 Mpa |

| Packing Dimensions | 570×620×1300 mm |

| Gross Weight | 85 kg |

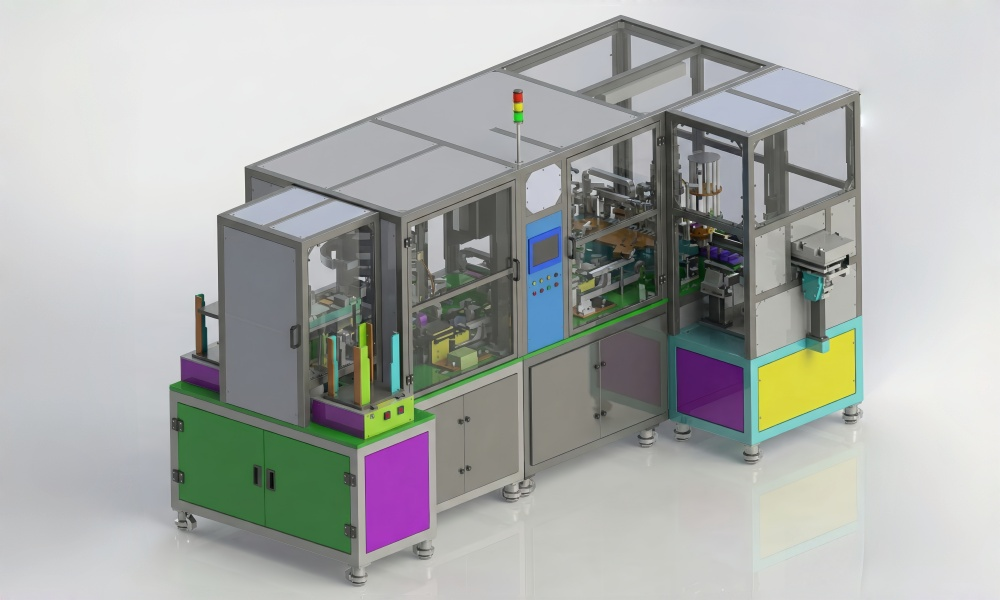

Automated equipment

About Us

Ningbo Shuntai Automation Co., Ltd.

Ningbo Shuntai Automation Co., Ltd. originated from the automation division of Ningbo Hongheng Precision Machinery Co., Ltd., and was established in 2015. After several years of development and accumulation, it achieved internal independent accounting in 2019 and officially changed its name to Ningbo Shuntai Automation Co., Ltd. in 2021. The company focuses on the research, development, production, and manufacturing of automotive parts, electronic components, and automation equipment, and is committed to providing customers with high-quality products and solutions.

Hongheng Precision was established

Riveting technology research and development

Establish equipment research R&D

Establish a smart manufacturing center

Shuntai Automation was established

Fully automatic servo riveting machine SOP

New riveting solutions for electric vehicles

Opened a riveting center with universities

3D Modeling

Our 3D modeling service is based on mainstream professional 3D design software, supporting seamless collaboration via compatibility with various common file formats. We employ full parametric modeling, enabling flexible and rapid model modifications to adapt to design adjustments and customization needs. Moreover, the automatic engineering drawing function realizes high-speed, efficient generation of professional technical documents, significantly enhancing design efficiency while guaranteeing the accuracy and standardization of deliverables.

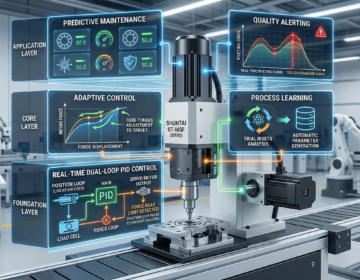

R&D Capabilities

We boast robust R&D capabilities backed by a team of senior designers with extensive industry experience. Adopting a collaborative innovation philosophy, our professional team executes closed-loop management throughout the R&D process, encompassing project initiation, design review, and iterative optimization. This systematic approach ensures each R&D project meets high-quality standards, enabling rapid responses to market and customer demands and laying a solid foundation for delivering reliable, competitive technical solutions.